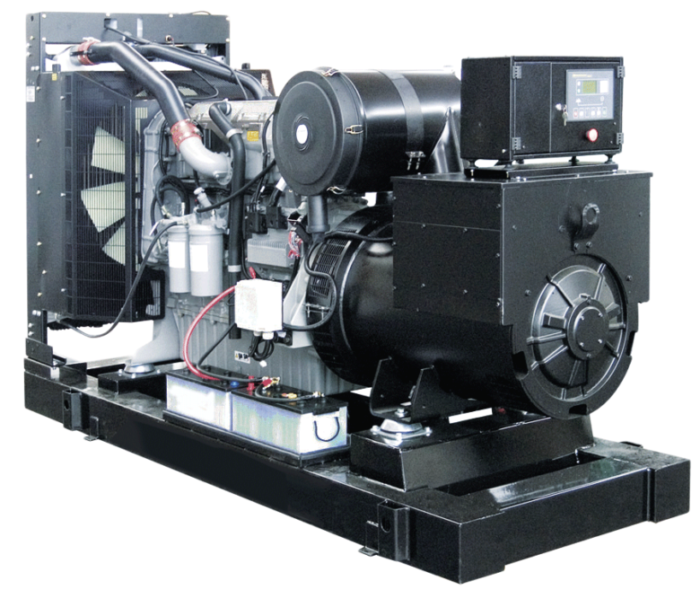

TENAX product line includes diesel generating sets, 1500/1800 rpm, liquid cooled, single-phase and threephase, rating from 5 to 3000 kVA. They are available both open skid and super-silenced, and can be equipped with industrial engines such as Cummins, Perkins, Scania John Deere, Volvo Penta, Kohler, Iveco, Deutz and Mitsubishi as well as with alternators of primary brands such as Leroy Somer, Stamford, Mecc Alte, Marelli.

Their canopies, designed to guarantee an excellent soundproofing level and optimal engine cooling, are made of hot galvanized steel and are polyester-powder painted to ensure weather protection. These generators are especially suitable for continuative use in industry and, in their super-silenced version with automatic control panel, also in the civilian sector.

> SOUNDPROOF VERSION

> OPEN VERSION

TECNOGEN Super Silent soundproof canopy provides a perfect cooling for the engine. The cooling airflow is forced through fixed circuits. The canopy is suitable for tropical ambient application.

The exhaust gas silencer is of residential type and is internally mounted. The canopy is of hot galvanized carbon sheet steel. The structure is fully bolted, fixed by special polyethylene seals, with no electrical parts.

All the panels can be easily removed. The canopy is equipped with doors of wide opening for easy access to generator set for easy maintenance operations. The doors’ locks are stainless steel and come with keys. The soundproofing materials are highly fire resistant and self-extinguishing. The sheet steel metal is pre-treated prior to being powder coated.

GALLERY

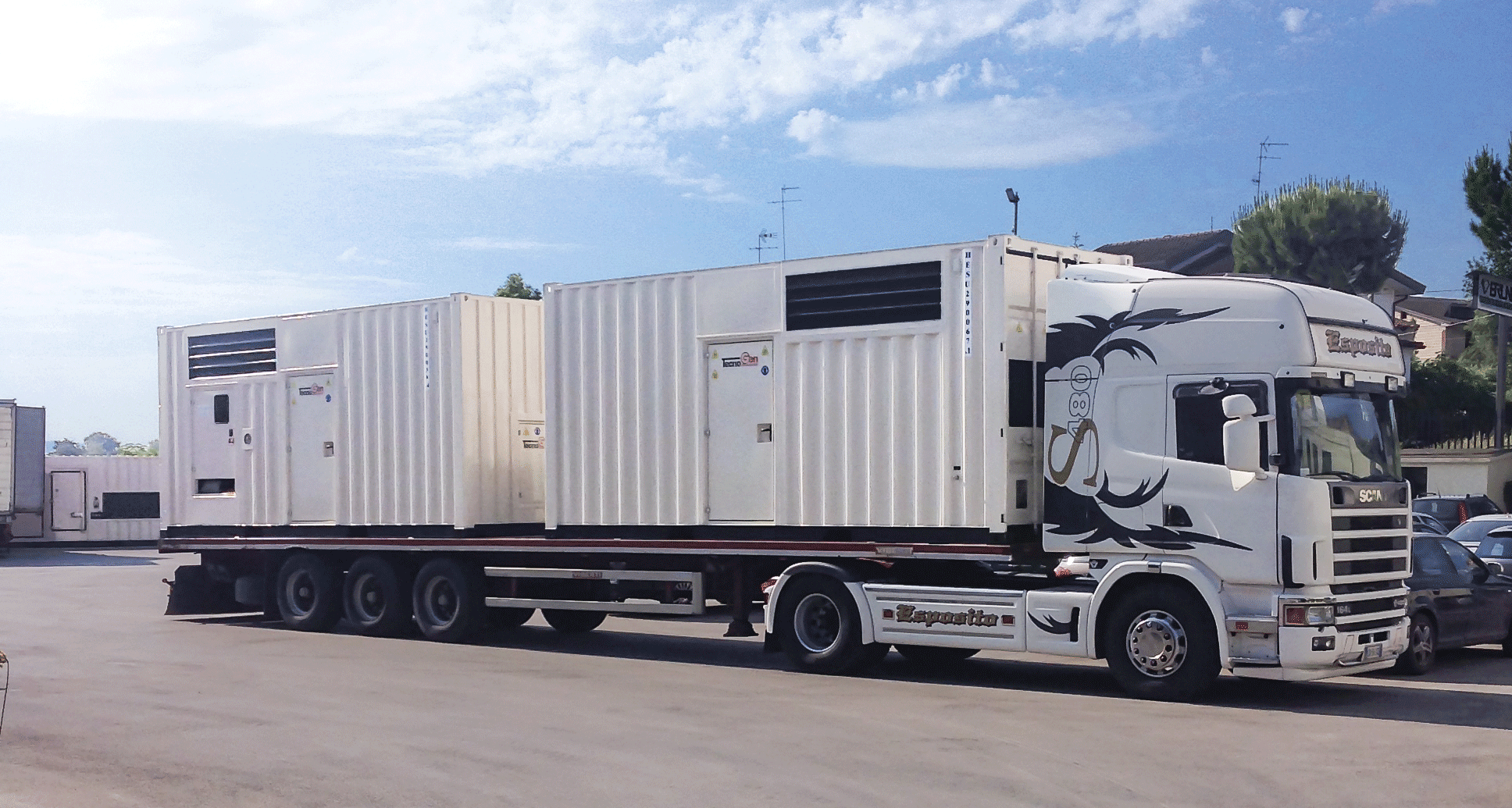

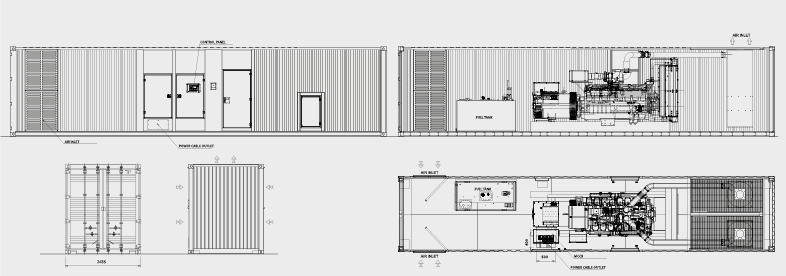

> SOUNDPROOF CONTAINERS

The soundproofing process has been realized not only through canopies but also by using 20‘ and 40‘ ISO-containers. Lowest noise level by using high density sound absorbing material and highly effective aeration and cooling system.

It is possible to achieve the lowest noise level thanks to high density sound absorbing material and highly effective aeration and cooling system.

> TENAX SC DESIGN

Control panel door with lexan viewing window on the short side

Wide access for radiator maintenance

Key lockable handle

> CONTAINER PAINTING PROCESS

On side is a photographic representation of the containers painting process made by TECNOGEN and covers containers 20’ box, 20’HC, 30’ box and 30’HC, 40’ box and 40’HC models, ISO certified. Containers are painted as it follows:

- Professional sand blasting in TECNOGEN industrial room with metal microspheres;

- Painting with liquid zinc – 2 coats;

- Primer covering before final liquid painting – 2 coats;

- High quality liquid painting in TECNOGEN painting industrial room.